Precision Mold Supplies: Elevating Metal Fabrication Standards

In the dynamic world of metal fabrication, the significance of quality cannot be overstated. At the forefront of this industry is the essential role played by precision mold supplies. These supplies serve as the backbone of any successful fabrication project, ensuring that components are manufactured with utmost accuracy and efficiency. The following sections delve into the various aspects of precision mold supplies and their impact on metal fabrication processes, especially for businesses like DeepMould.net.

The Role of Precision Mold Supplies in Metal Fabrication

Precision mold supplies encompass a variety of components and materials that ensure the accurate shaping and formation of metal pieces. These supplies include:

- Mold bases

- Mold cores

- Mold cavities

- Injection molds

- Thermal control systems

Each element plays a crucial role in the production process, allowing manufacturers to create components that meet the strictest tolerances and specifications.

Why Businesses Should Prioritize Quality

In the competitive landscape of metal fabrication, selecting high-quality precision mold supplies can set a company apart from its competitors. Here are several key reasons why businesses need to invest in premium supplies:

- Increased Efficiency: Quality supplies lead to faster production times. Well-designed molds reduce the need for adjustments and rework, significantly speeding up the manufacturing process.

- Cost-Effectiveness: Although the initial investment may be higher, quality precision mold supplies often result in lower operating costs over time due to reduced waste and increased lifespan of the molds.

- Enhanced Product Quality: Precision in mold making translates directly into the quality of the finished products. High-quality molds ensure that every piece produced adheres to the required specifications and tolerances.

- Greater Flexibility: Advanced mold supplies can accommodate a range of designs and modifications. This flexibility allows businesses to adapt quickly to new market demands and customer requirements.

Components of Precision Mold Supplies

The production of precision molds involves several intricate components. Understanding these components is crucial for businesses looking to enhance their manufacturing capabilities:

1. Mold Bases

Mold bases are the foundation of every mold. They provide structural support and facilitate the correct alignment of mold components. Quality mold bases are made from durable materials that withstand repeated use while maintaining structural integrity.

2. Cavity and Core Inserts

The cavity and core inserts are pivotal in determining the shape of the final product. They must be manufactured with extreme precision to avoid defects such as sink marks or warping. Advanced machining technologies, such as CNC machining, are often employed to create these inserts.

3. Ejector Systems

Once the component is formed, the ejection system plays a critical role in safely and efficiently removing the finished product from the mold. Quality ejector pins and systems ensure minimal damage to both the product and the mold itself.

4. Cooling and Heating Components

The temperature control systems integral to precision molds ensure that the molding process occurs under optimal conditions. Effective cooling channels help maintain uniform temperatures, preventing defects and shortening cycle times.

The Process of Selecting Precision Mold Supplies

Selecting the right precision mold supplies requires careful consideration. Here are some steps businesses should follow:

1. Assess Your Production Needs

Understanding the specific requirements of your projects is paramount. Determine the types of materials, production volume, and design specifications necessary for your molds.

2. Evaluate Material Options

Different mold materials offer varying degrees of durability and thermal conductivity. Common materials include:

- Steel - Known for its hardness and durability, making it suitable for high-volume production.

- Aluminum - Lightweight and cost-effective, ideal for low-volume or prototype runs.

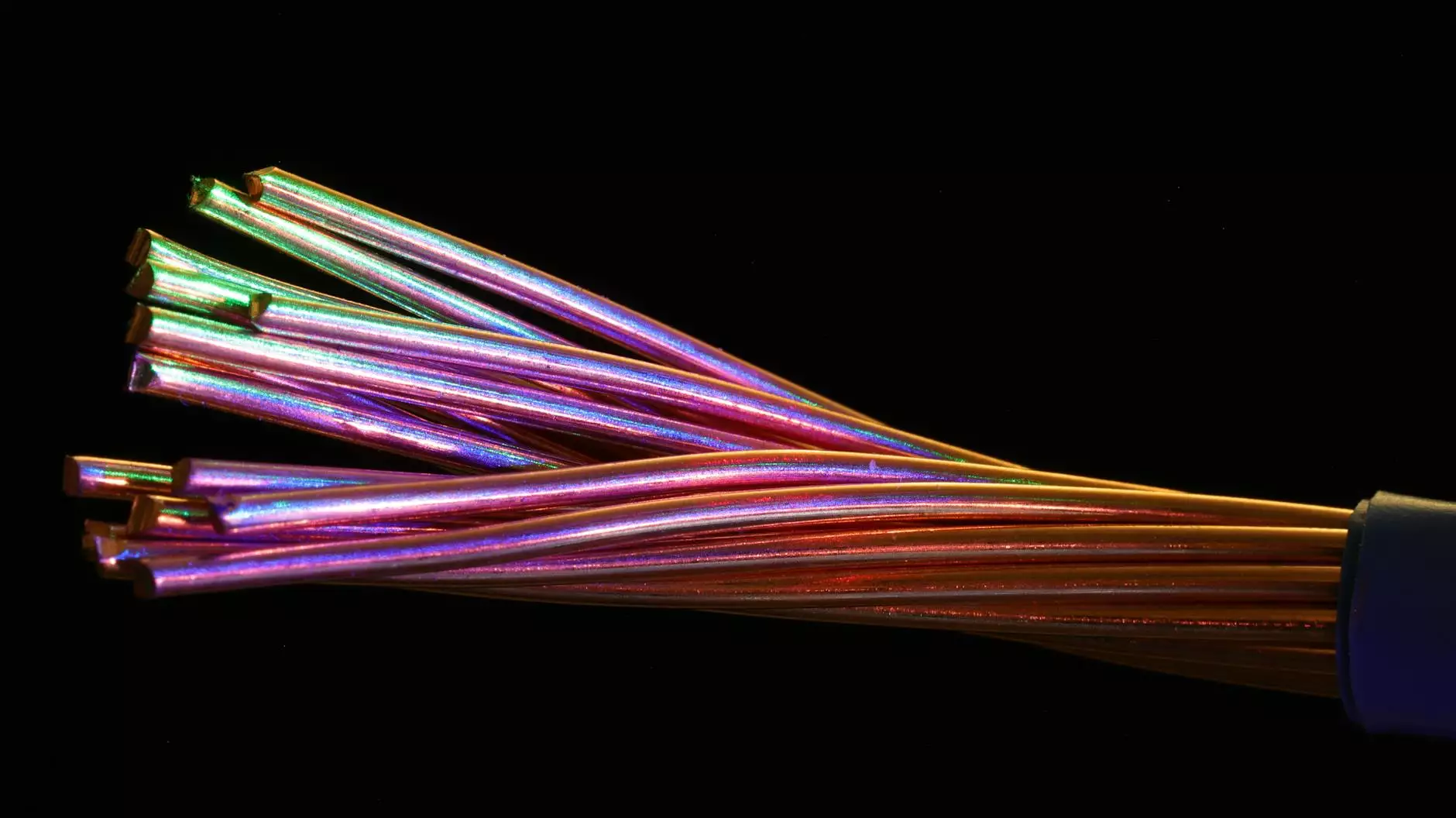

- Copper alloys - Excellent thermal conductivity, beneficial for molds requiring effective heat transfer.

3. Research Suppliers

Partnering with reputable suppliers ensures access to high-quality precision mold supplies. Evaluate suppliers based on their expertise, customer reviews, and material certifications.

4. Consider Lead Times

In a fast-paced industry, time is of the essence. Ensure that your chosen supplier can meet your timelines for delivery without compromising on quality.

Cost Considerations in Precision Mold Supplies

Understanding the costs associated with precision mold supplies is essential for budgeting and investment decisions:

1. Initial Investment vs. Long-term Value

While high-quality molds may incur a higher initial investment, they often yield substantial long-term savings by minimizing defects and downtime. Comparing total cost of ownership rather than just upfront costs is crucial.

2. Maintenance and Repair Costs

Regular maintenance of molds can prevent costly repairs and extend their lifespan. Investing in high-quality supplies often leads to decreased maintenance needs and lower repair costs.

Future Trends in Precision Mold Supplies

The future of precision mold supplies in the metal fabrication industry is bright, with several exciting trends emerging:

1. Automation and Robotics

Integration of automation in mold production can enhance precision and consistency. Automated systems reduce human error and increase production rates, paving the way for advanced manufacturing processes.

2. 3D Printing Technology

3D printing is revolutionizing the way molds are produced. This technology allows rapid prototyping and custom mold creation, minimizing lead times and costs.

3. Sustainable Practices

As sustainability becomes increasingly important, businesses are looking for eco-friendly mold supplies and practices. Using recyclable materials and reducing waste during production are key objectives for the future.

Conclusion

In summary, precision mold supplies are an indispensable aspect of the metal fabrication industry. By investing in high-quality components and staying informed about the latest trends, businesses can ensure they remain competitive and produce exceptional products. With a focus on quality, efficiency, and continuous improvement, companies like DeepMould.net can leverage precision mold supplies to enhance their capabilities and succeed in an ever-evolving market.

Get Started with Precision Mold Supplies Today!

Are you ready to elevate your metal fabrication projects? Explore the extensive range of superior precision mold supplies available at DeepMould.net and experience the difference that quality makes in your production processes.